LAMINATING FLOORING PRODUCTION LINE

V-SHARP GROOVE PAINTING LINE

Used for the floor V-groove, use water-based paint,first short side coating and drying, then long side. The floor with paint improved waterproof properties, which is beneficial to the floor of the joining together.

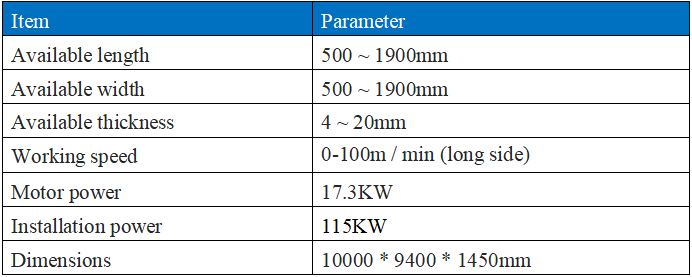

Product information

Machine structure

The V-sharp groove painting Line equips Side painting unit、Side Heating unit、Bely conveyor unit、Transfer conveyor、Long side painting Unit、Long side heating unit、Out feed general heating conveyor(2 sets).

The operators or robot hand load the floor in the magazine of the side painting unit, The floor were passed through the side painters by the pushers on the chain conveyor. The water base paint was get dry by 3 sets of infrared heating lights. Floor was conveyed to the transfer conveyor after cooling by the belt conveyor. After being conveyed into the transfer conveyor, it is transported into the long-side painting unit, and the long-side V-groove is painted. After the paint is applied, it is dried by two sets of heating units, the production is finished after cooling fans in the end.