What machines are required to install a SPC Flooring production line?

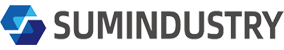

1. SPC flooring production line

SPC flooring production line is one of the most important production process for producing SPC flooring. spc floor extrusion line

converts the mixed raw materials into the SPC core layer by the double-cone screw and die, and laminating the wear-resistant layer and decor film on the core layer with emboss roller, and finally form the large board of the SPC floor.

2. UV coating machine

UV coating line is designed for coating UV varnish on SPC floor,WPC floor,WPC floor,LVT floor,PVC marble sheet,PVC cabinet board etc,which can give the feathers of anti scratch,bacteria roof,stain resistance.Each Coating roller controlled by individual motor to make exact coating quantity and effect.

3. Cutting and slotting machine

Cutting and slotting machine is used to cut the flooring board into several pieces automatically. This machine is applicable for SPC flooring, with the latest technology. It is featured by the advantage of high efficiency, quick switching, various product specifications, labor saving and cost saving, etc.Customers can choose the machine type according to your different specifictions and materials ,or contact us for customization.

4. UV edge Coating machine

With the trend of the times, more and more customers like SPC floors with painted V-grooves. The painted V-shaped groove makes the floor look more beautiful, the link is more stable and it is more popular in the global market. Researched and developed a machine that can spray SPC floor V-shaped grooves.

5. IXPE laminating

Silent pads are used to produce composite silent pads on the back of WPC or SPC floors or PE film SPC floor bottoms. They can also be compounded with absorbent silent pads to make the floor more flexible, feel more comfortable, and have an excellent mute effect.

6. Dust colleting system

2. Decent has developed a wide range of products and systems including dust collectors,piping/ducting,fans,conveyors,silos and automated control systems,these systems make it possible for customers to not only achieve a good working environment,but also recyle wood waste,which can represents a large economic value.

SPC flooring parameter

Density: 2T/CBM, 8kg/sqm of 4mm thick--8kg weight

Thickness: 3.2mm, 4mm, 4.5mm, 5mm, 6mm

Wear layer: 0.3mm,0.5mm

Size: 6"x36", 6"x48", 7"x48", 18"x18"

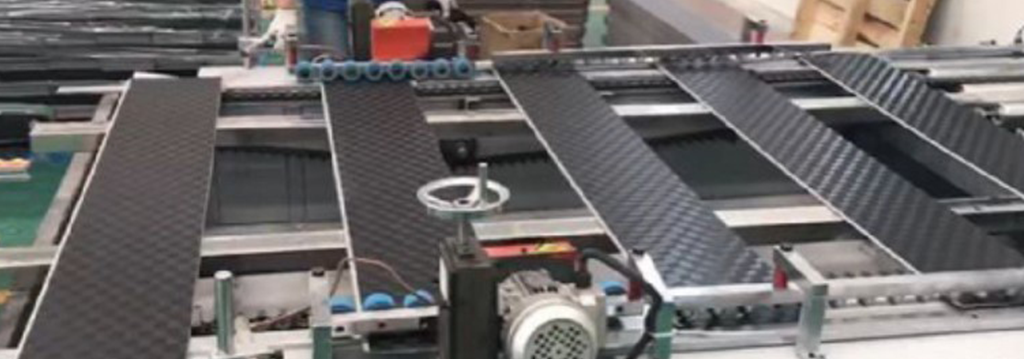

SPC flooring stype

Advantages of SPC flooring

(1) Ecological and environmental protection;

(2) Fire protection and fire protection grade B1, second only to stone;

(3) Various surface treatments (concave-convex pattern, hand-grabbing pattern, pair pattern, mirror pattern);

(4) Wear resistance, wear resistance grade T;

(5) Moisture-proof, no deformation when exposed to water, can be used in kitchens, bathrooms, basements, etc;

(6) The colors are beautiful and diverse, the mosaic construction is seamless, and the installation is convenient and quick;

(7) Anti-slip, more astringent when exposed to water, not easy to fall;

(8) Noise reduction, comfortable walking foot feel, flexible, not easy to be injured when falling down;

(9) Daily maintenance does not require waxing treatment, it can be wiped with a towel or wet mop;

Other issues you care about.

1. What are the latch types of SPC flooring?

Lock: Unilin, Valinge, I4F.

2. How often does the tool need to be sharpened? How long is the service life?

Sharp the saws after about 20,000sqm floor, and change the saws after about 10 times sharpping.

3. What raw materials are needed to make SPC flooring

PVC, calcium carbonate, recycled material, stabilizer, CPE, ACR, Stearic, PE wax

4. Application of SPC flooring.

Widely used in indoor homes, hospitals, learning, office buildings, factories, public places, supermarkets, commerce, stadiums and other places

Why choose SUM as your supplier?

1. Professional design

Our engineers team will draw the layout according to customer’s factory space and production requirements. Each equipment location,passage will be designed reasonably to meet safety production.

2. Advanced equipment

SUM has specialized in flooring production line for more than decade years. All the devices are produced with great care to make sure perfectly running in customer’s factory.

3. Humanized after-service

SUM provides quality guarantee,all the faulty parts will be recalled without any cost. Professional engineers will be sent to customer’s factory to help stall the production line until it runs well. Provide technical support within 1 hour to ensure that customers can solve problems in short time.

Short Cycle Press Machine

- Home

- >

- Short Cycle Press Machine

SPC flooring production line

What’s the SPC Flooring?SPC is the abbreviation of Stone Plastic Composites. The main raw material is polyvinyl chloride resin. The SPC substrate is extruded by an extruder combined with a T-die. The PVC is wear-resistant with a three-roll or four-roll calender. The layer, PVC color film and SPC substrate are laminated and embossed by heating at one time. No glue is used in the production process.